HPH 1/32 Aviatik Berg D1

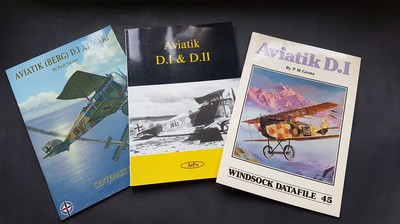

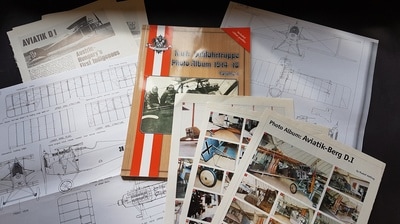

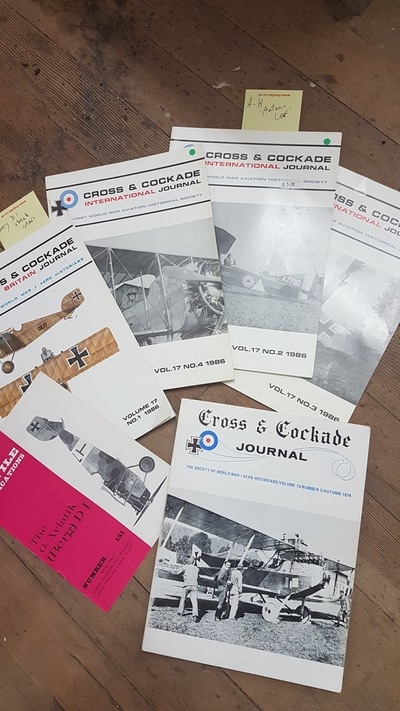

Surprised, as we all were, by the announcement of this kit from the Czech resin specialists and partly because I was hoping to produce a kit of this myself one day (!), I had to buy one and am pleased to report that I'm very glad I did....

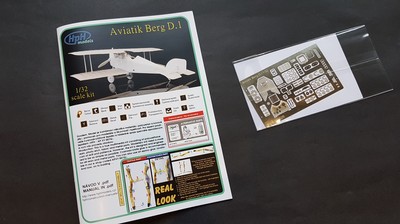

Very promptly delivered and packed sensibly, if a little predictably, in a plain card box with label stuck on the top with a good illustration of the Berg D1 in action.

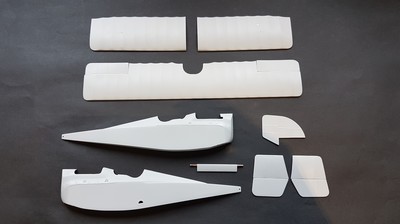

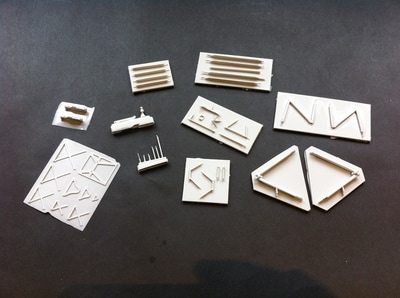

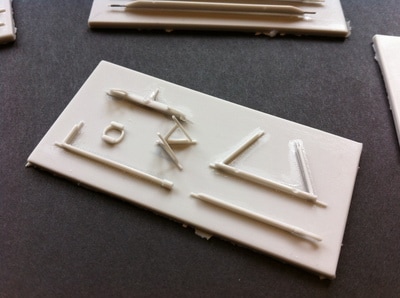

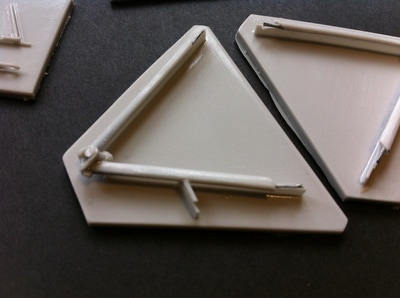

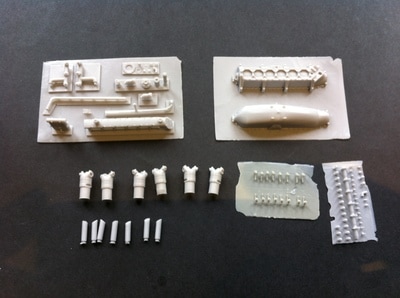

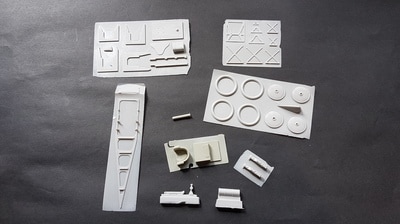

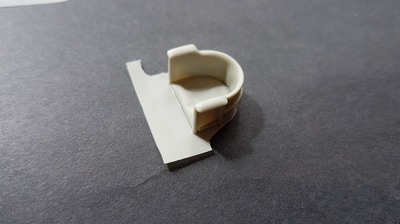

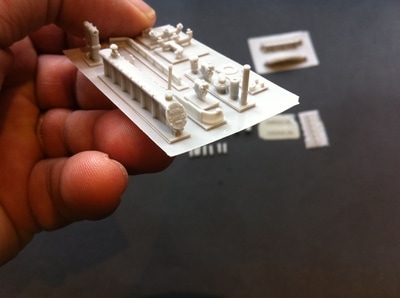

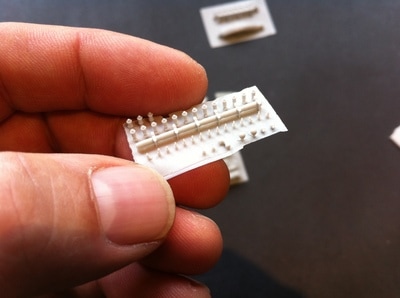

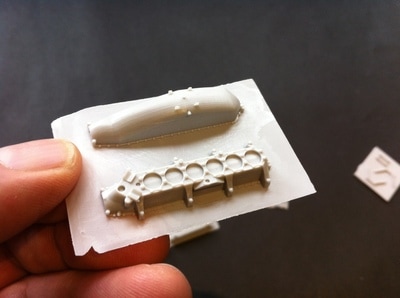

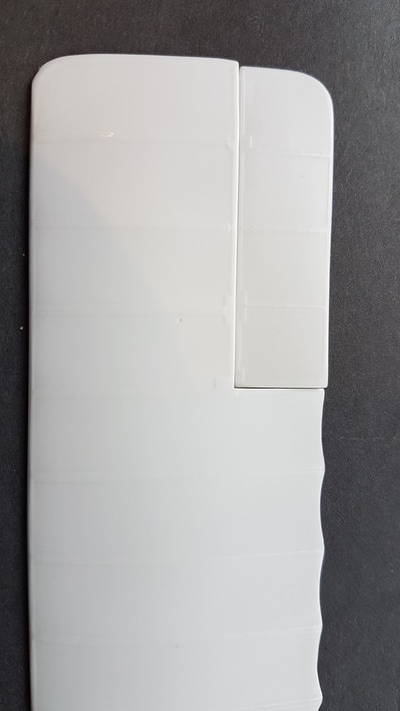

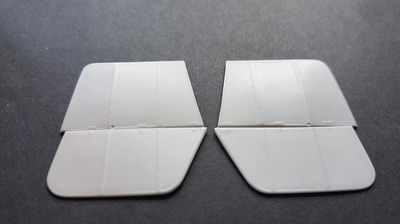

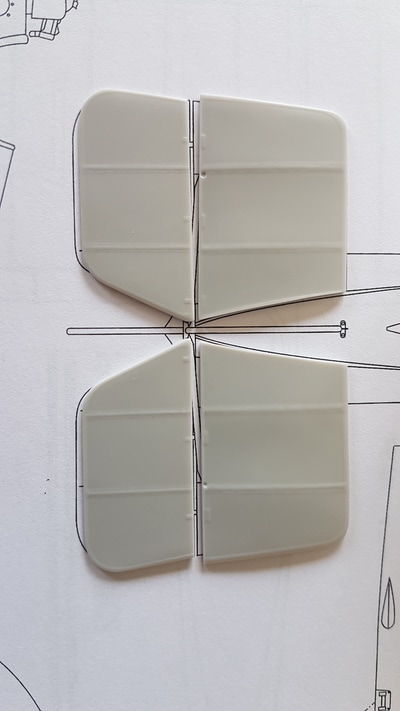

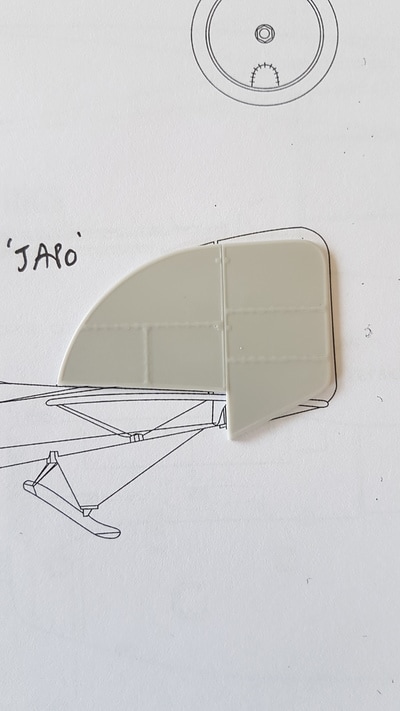

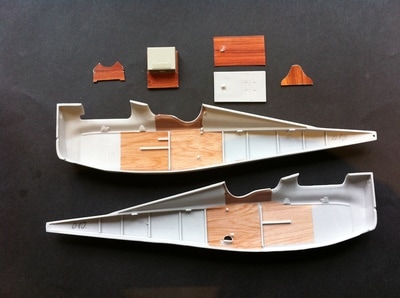

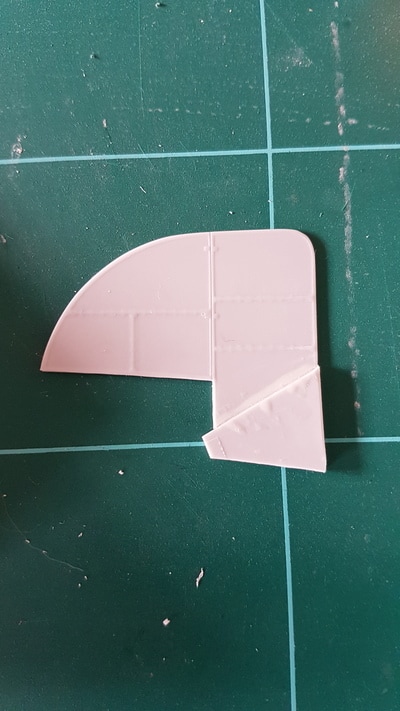

Opening the box reveals four card-separated compartments stuffed with beautifully cast resin pieces. Some cast on rather heavy "wafers" requiring careful sawing and freeing, sanding etc., others have very fine wafers that took very little effort to remove.

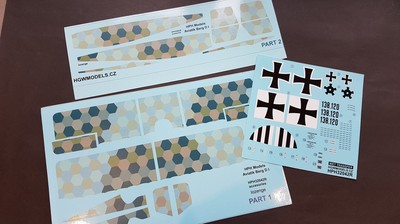

The "Hex" camo has been dealt with in two ways. With the kit you get dye cut mask sets and a small but well printed decal sheet with national markings but only one aircraft is represented...one serial number (providing the whole numerical range would have given the modeller options, surely?) as well as relevant stencils, very nicely done plaques and instruments.

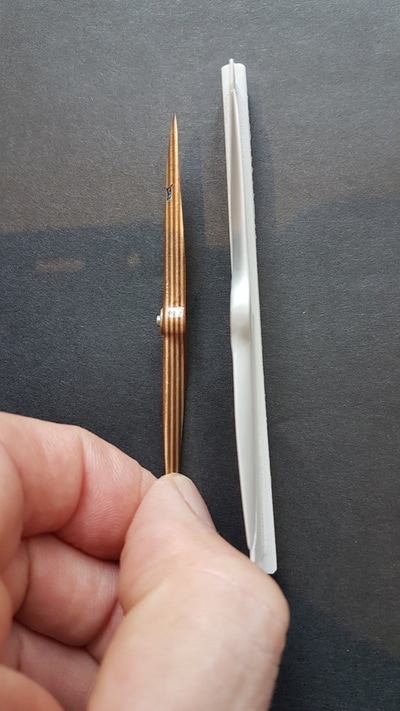

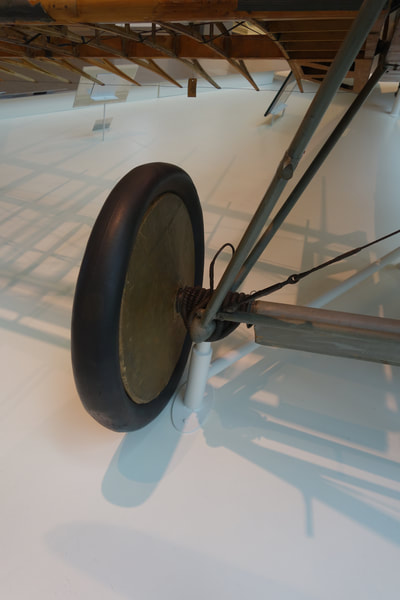

Struts and undercarriage have wire cast within for strength. Mine had a few air bubbles, easily remedied with a talc and superglue mix.

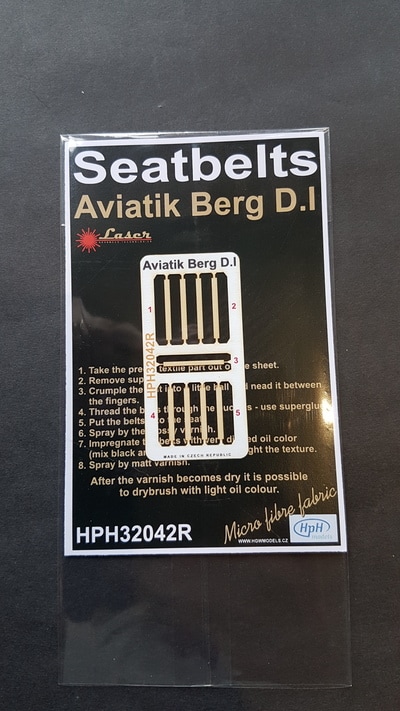

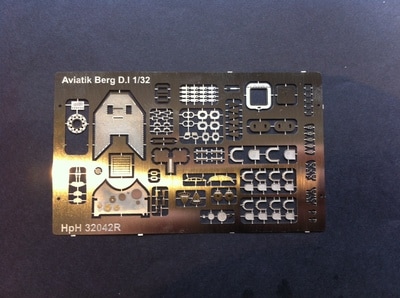

HGW "fabric" effect seatbelts and some workmanlike photo-etch add some detail.

An option is offered on the website for buying alternative "Hex" printed decals, which have a curious, washed out appearance (an attempt to replicate Ronny Barr's "safe" rendering of these colours) and a rather elaborate masking set for the rib tapes for around £18.00...I'm all for having options but decals are a "must" in a kit - surely?

I was dying to get started and had many of the major components released from the casting blocks, cleaned up and soaked in degreaser in around three hours. Enjoying every minute and still pinching myself that a 1/32 Aviatik Berg was actually now a reality!...

Very promptly delivered and packed sensibly, if a little predictably, in a plain card box with label stuck on the top with a good illustration of the Berg D1 in action.

Opening the box reveals four card-separated compartments stuffed with beautifully cast resin pieces. Some cast on rather heavy "wafers" requiring careful sawing and freeing, sanding etc., others have very fine wafers that took very little effort to remove.

The "Hex" camo has been dealt with in two ways. With the kit you get dye cut mask sets and a small but well printed decal sheet with national markings but only one aircraft is represented...one serial number (providing the whole numerical range would have given the modeller options, surely?) as well as relevant stencils, very nicely done plaques and instruments.

Struts and undercarriage have wire cast within for strength. Mine had a few air bubbles, easily remedied with a talc and superglue mix.

HGW "fabric" effect seatbelts and some workmanlike photo-etch add some detail.

An option is offered on the website for buying alternative "Hex" printed decals, which have a curious, washed out appearance (an attempt to replicate Ronny Barr's "safe" rendering of these colours) and a rather elaborate masking set for the rib tapes for around £18.00...I'm all for having options but decals are a "must" in a kit - surely?

I was dying to get started and had many of the major components released from the casting blocks, cleaned up and soaked in degreaser in around three hours. Enjoying every minute and still pinching myself that a 1/32 Aviatik Berg was actually now a reality!...

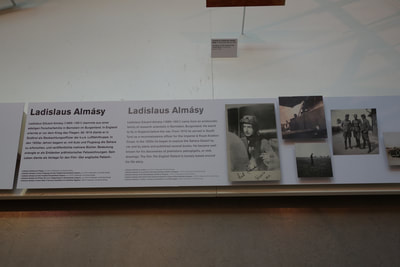

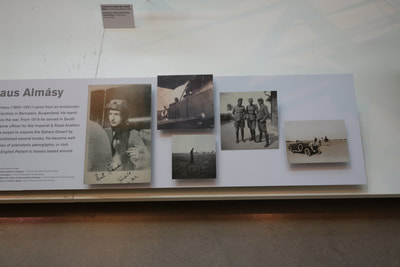

Aviatik Berg DI Walkaround

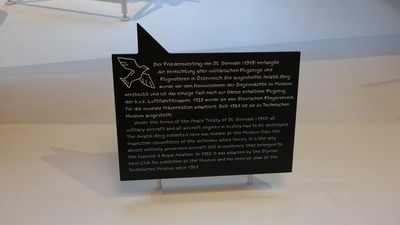

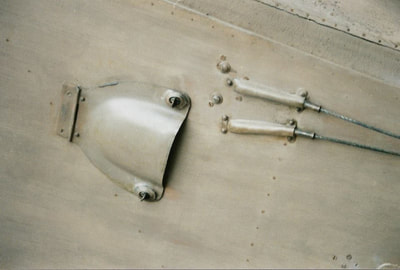

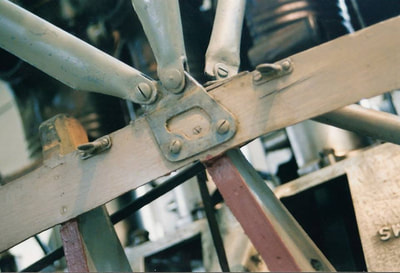

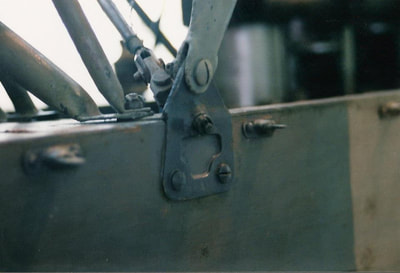

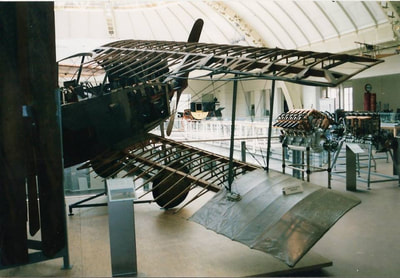

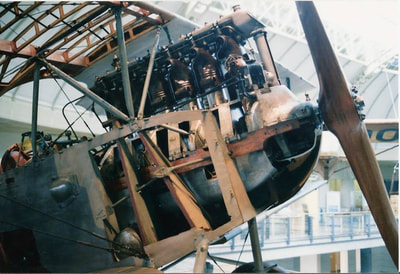

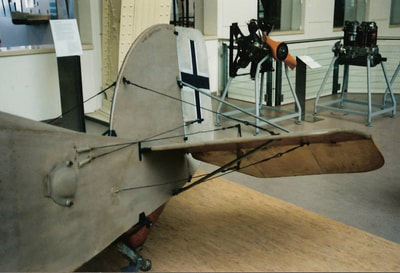

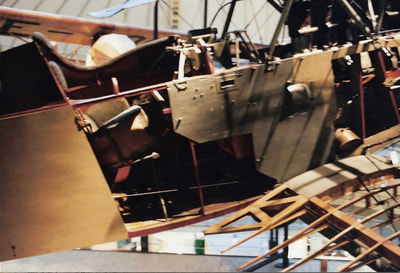

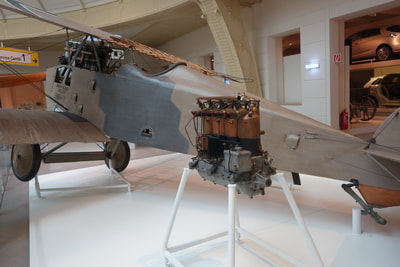

Aviatik Berg D.I exhibited at the Vienna Technical Museum

The Aviatik (Berg) DI was the first indigenous fighter aircraft built in Austro-Hungary. Oberingenieur Julius von Berg (hence the name "Berg"), appointed as head designer at the Aviatik company, designed the first prototype late 1916.

Work on the prototype began in August 1916, while the first flight of the Aviatik (Berg) DI prototype, marked 30.14, took place at 16th October 1916 at Aspern, unfortunately killing the test pilot.

Further modifications were made, and three more prototypes of the Aviatik (Berg) DI were manufactured, labeled 30.19 (for tests on the ground), 30.20 (for tests in flight) and 30.21 (as a reserve airframe).

Tests of the modified aircrafts were positive and the first unit to receive the first serial batch of the Aviatik (Berg) DI was Fluggeschwader I (FLG I, later to be renamed to Flik 101G) on the Divacca airfield (Italy)

The Aviatik (Berg) DI was manufactured under license by a numbers of subcontractors.

Aviatik built the 38, 138.238 and 338 series

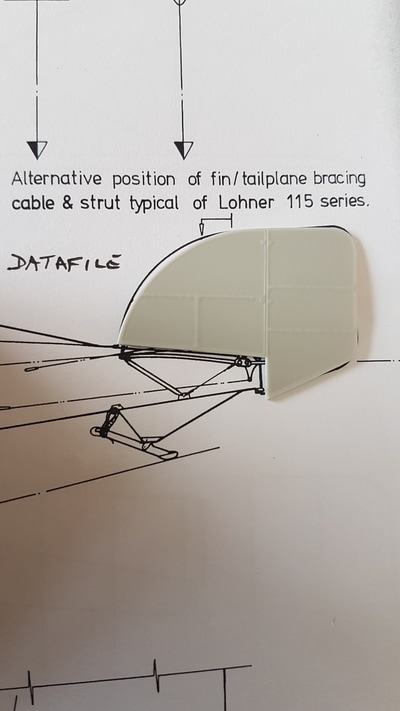

Lohner built the 115 and 315 series

LLoyd manufactured the 48, 248 and 348 series.

MAG built the 84 and 92 series

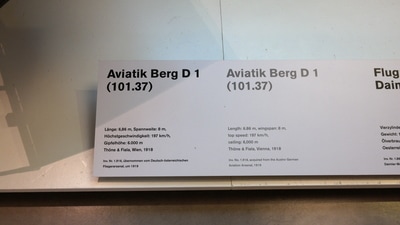

Thone & Fiala manufactured the 101 and 201 series

WKF built the 184, 284 and 384 series.

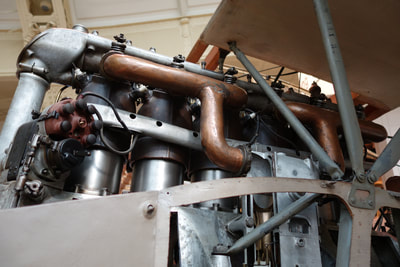

The main differences between the series were the engines (the Aviatik (Berg) used Austro-Daimler engines),structural modifications, gun modifications and radiator modifications.

Until the 31st October 1918 a number of 677 Aviatik (Berg) DI airframes of all batches were handed over to the Austro-Hungarian Airforce.

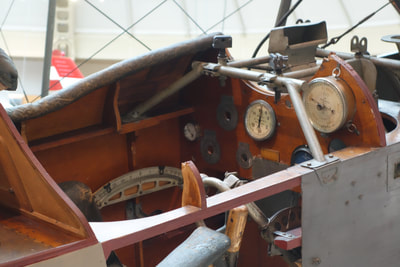

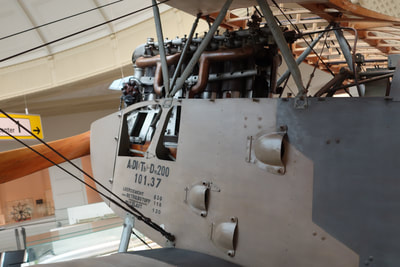

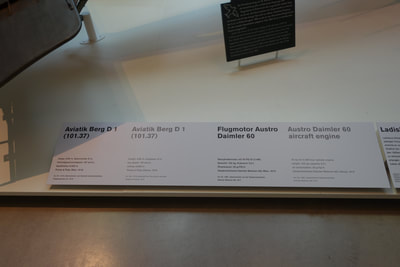

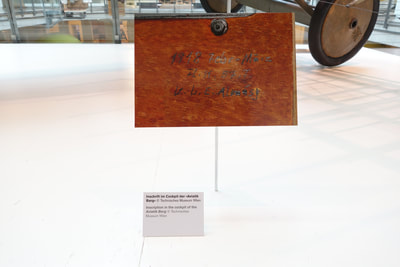

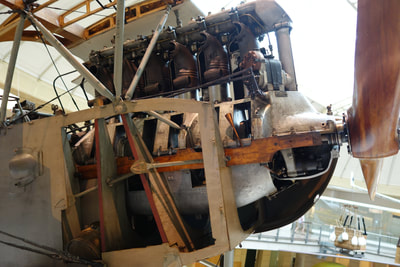

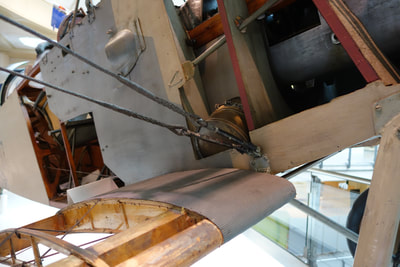

This particular Aviatik Berg DI (101.37, made by Thone & Fiala) is exhibited at the Vienna Technical Museum, 4th floor, along with some preserved World War One engines. The second surviving Aviatik Berg DI is on display in the USA.

I had the opportunity to visit this museum in november 2005 and eagerly took as many shots as i could.

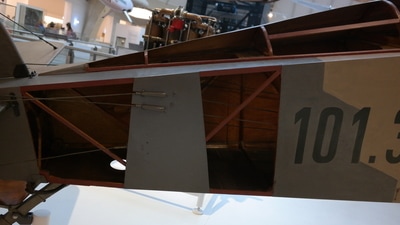

The Aviatik Berg DI series 101 shows several differences from other series:

-reinforced wing structure (the number of spars on both lower and upper wing doubled)

-reinforced fuselage structure

-cockpit-mounted guns (Schwarzlose M16)

-more powerful engine (Austro-Daimler 200 HP)

Text and photos copyright protected, courtesy of Andi Szekeres @ www.idflieg.com

The Aviatik (Berg) DI was the first indigenous fighter aircraft built in Austro-Hungary. Oberingenieur Julius von Berg (hence the name "Berg"), appointed as head designer at the Aviatik company, designed the first prototype late 1916.

Work on the prototype began in August 1916, while the first flight of the Aviatik (Berg) DI prototype, marked 30.14, took place at 16th October 1916 at Aspern, unfortunately killing the test pilot.

Further modifications were made, and three more prototypes of the Aviatik (Berg) DI were manufactured, labeled 30.19 (for tests on the ground), 30.20 (for tests in flight) and 30.21 (as a reserve airframe).

Tests of the modified aircrafts were positive and the first unit to receive the first serial batch of the Aviatik (Berg) DI was Fluggeschwader I (FLG I, later to be renamed to Flik 101G) on the Divacca airfield (Italy)

The Aviatik (Berg) DI was manufactured under license by a numbers of subcontractors.

Aviatik built the 38, 138.238 and 338 series

Lohner built the 115 and 315 series

LLoyd manufactured the 48, 248 and 348 series.

MAG built the 84 and 92 series

Thone & Fiala manufactured the 101 and 201 series

WKF built the 184, 284 and 384 series.

The main differences between the series were the engines (the Aviatik (Berg) used Austro-Daimler engines),structural modifications, gun modifications and radiator modifications.

Until the 31st October 1918 a number of 677 Aviatik (Berg) DI airframes of all batches were handed over to the Austro-Hungarian Airforce.

This particular Aviatik Berg DI (101.37, made by Thone & Fiala) is exhibited at the Vienna Technical Museum, 4th floor, along with some preserved World War One engines. The second surviving Aviatik Berg DI is on display in the USA.

I had the opportunity to visit this museum in november 2005 and eagerly took as many shots as i could.

The Aviatik Berg DI series 101 shows several differences from other series:

-reinforced wing structure (the number of spars on both lower and upper wing doubled)

-reinforced fuselage structure

-cockpit-mounted guns (Schwarzlose M16)

-more powerful engine (Austro-Daimler 200 HP)

Text and photos copyright protected, courtesy of Andi Szekeres @ www.idflieg.com

Photos copyright protected, courtesy of David Hardie